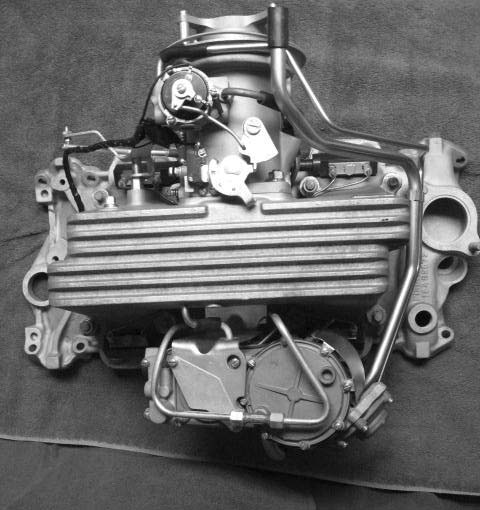

Repairs are a specialty. Rebuilding a fuelly unit is fun enough but finding a way to repair rare and unique parts is a challenge in and of itself. We welcome these challenges. Commonly we see parts that have been “serviced” by someone without a thorough understanding of design or the materials that the parts was constructed with. If you can name it, we have probably seen it. Worn, dropped, or damaged parts can lead to broken pot metal and aluminum castings, cracked covers, split fuel inlet female fittings, oversized cover plate screw holes, worn or ovaled out brass pivot holes, or leaking fuel meter inlets.

Other common repairs can include cracked plenum feet, missing corners of fuel meter bowls, leaking fuel spider lines, and split 4360 balance tube fuel meter cover ports. Most of the time, we can work to repair these pieces. We have successfully repaired both sand-cast and die-cast parts. Various repairs are undetectable.

Futo And Son

For example, when a plenum is dropped or when the feet are overtightened, small cracks or fissures are formed leading to vacuum leaks or poor performance. Broken mounting tabs, stripped threaded holes, and cracked housings present a challenge to the owner. We will work with the owner to suggest the best possible solution. When cosmetics are as important as the functionality of a properly rebuilt FI unit, we pay attention to these details. We minimize weld appearances when possible to preserve the value of your investment. Depending on the wear or damage, we will suggest a cosmetic treatment to minimize repairs.

When your FI plenum has been sleeping too long and a small rodent determines to take up residence, we work to restore the original appearance when converting your mouse house back to a functional unit. We work with customers to determine which finish is appropriate for your car. We will even help you relocate the mouse if you have to evict him.